Carpet Tape

Our high-strength tapes join carpets under the most demanding conditions.

Quality carpet tape that meets installers' needs

ADVANCED MANUFACTURE

BBS makes superior carpet tapes using modern manufacturing combined with our traditional know-how. We select high-grade resins with noticeably less smoke and odour – but without compromising the holding power you need at the seam. Our SureLok® straight webbing perfectly aligns the seam, preventing opening under tension. Our hotmelt and fibreglass are fused together under a chilled roller to create the strongest bonded backing for carpet joins. Our silicon-coated paper provides excellent release over all underlays.

LOW SMOKE AND ODOUR RESINS

Fumes released from lower-grade resins are an unhealthy hazard for installers. They can also trigger smoke alarms and irritate homeowner and their pets. Sureseam® carpet tapes use expensive low-smoke and odour resins in their formulations to eliminate these hazards.

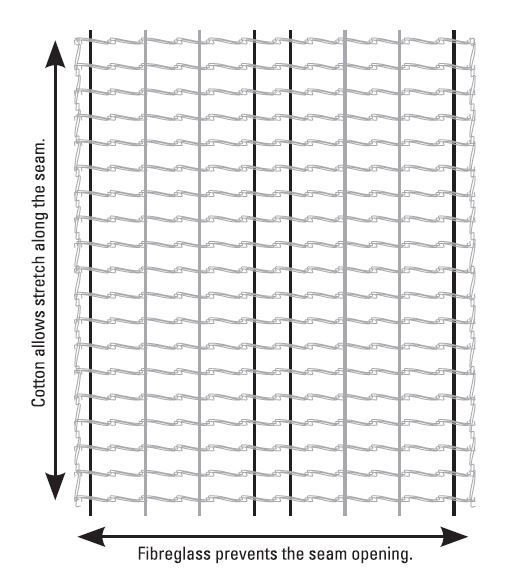

SURELOK® STRAIGHT WEBBING

Our fibreglass and cotton webbing perfectly aligns across the seam without warp or bow, so there is no slack when the seam is stretched. Straight webbing creates an even tension at the join, which reduces carpet peaking.

FUSED HOTMELT & FIBREGLASS

Sureseam® carpet tape is made through a chilled roller that fuses together the fibreglass strands with the hotmelt. Surrounding and imbedding the fibreglass within the hotmelt forms the strongest bonded backing for joining carpet.

SILICON RELEASE PAPER

Sureseam® tapes are all silicon release coated on the back for a quick release over all types of underlay.

WIDE (PLATEAU) TAPE

Selected Sureseam® tapes contain wider ‘plateaus’ of hotmelt in the centre for the join. More hotmelt focused at the centre of the seam helps to reduce peaking by firmly holding down the join edges.

FLEXIBLE, EASY GLIDE HOTMELT

Sureseam® hotmelt is carefully formulated to make it soft and flexible. This allows the installer to iron quickly down the seam.