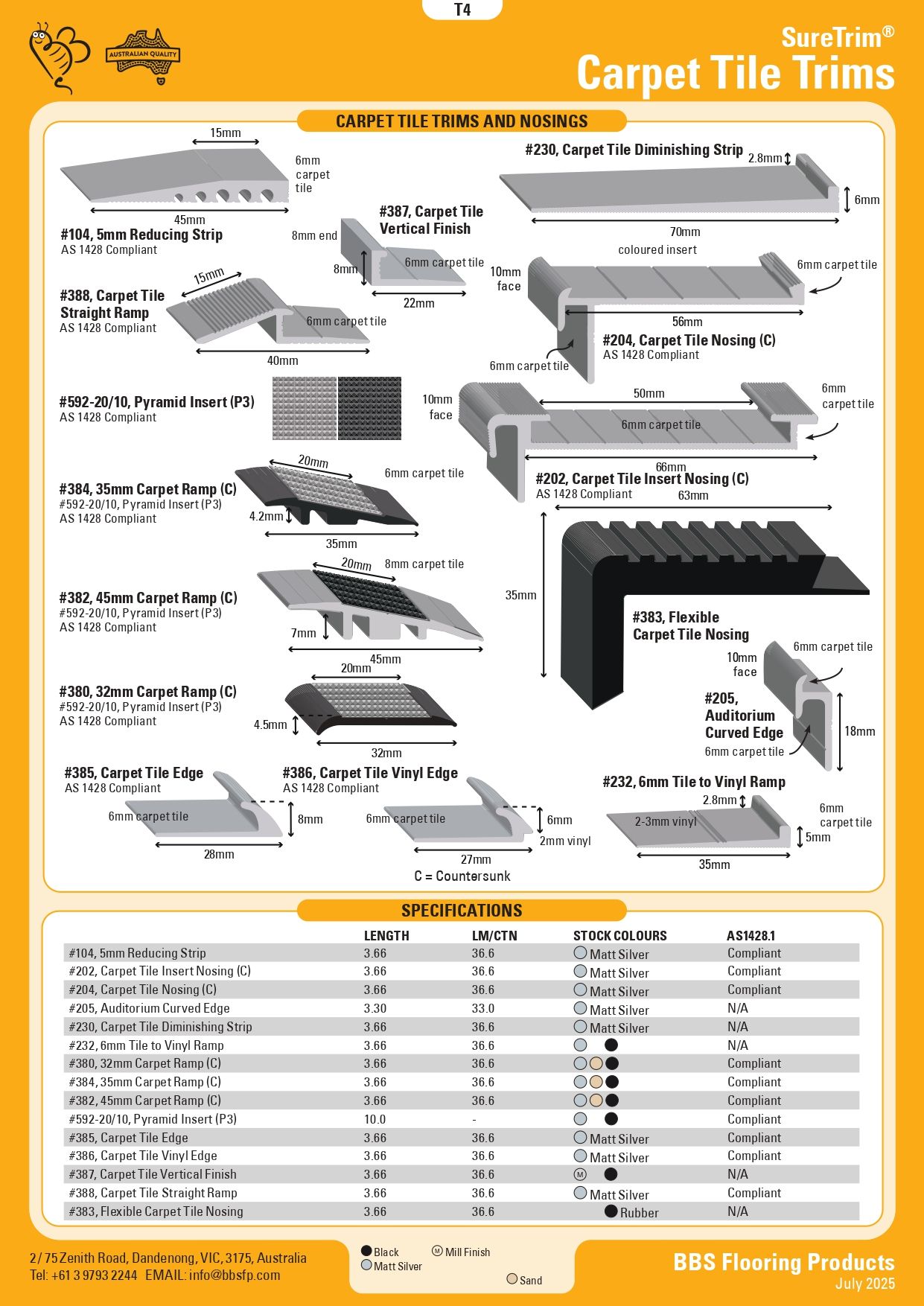

Flooring trims and transitions designed and developed in Melbourne.

Safe, reliable transitions

A transition for every application.

Ideal for contractors

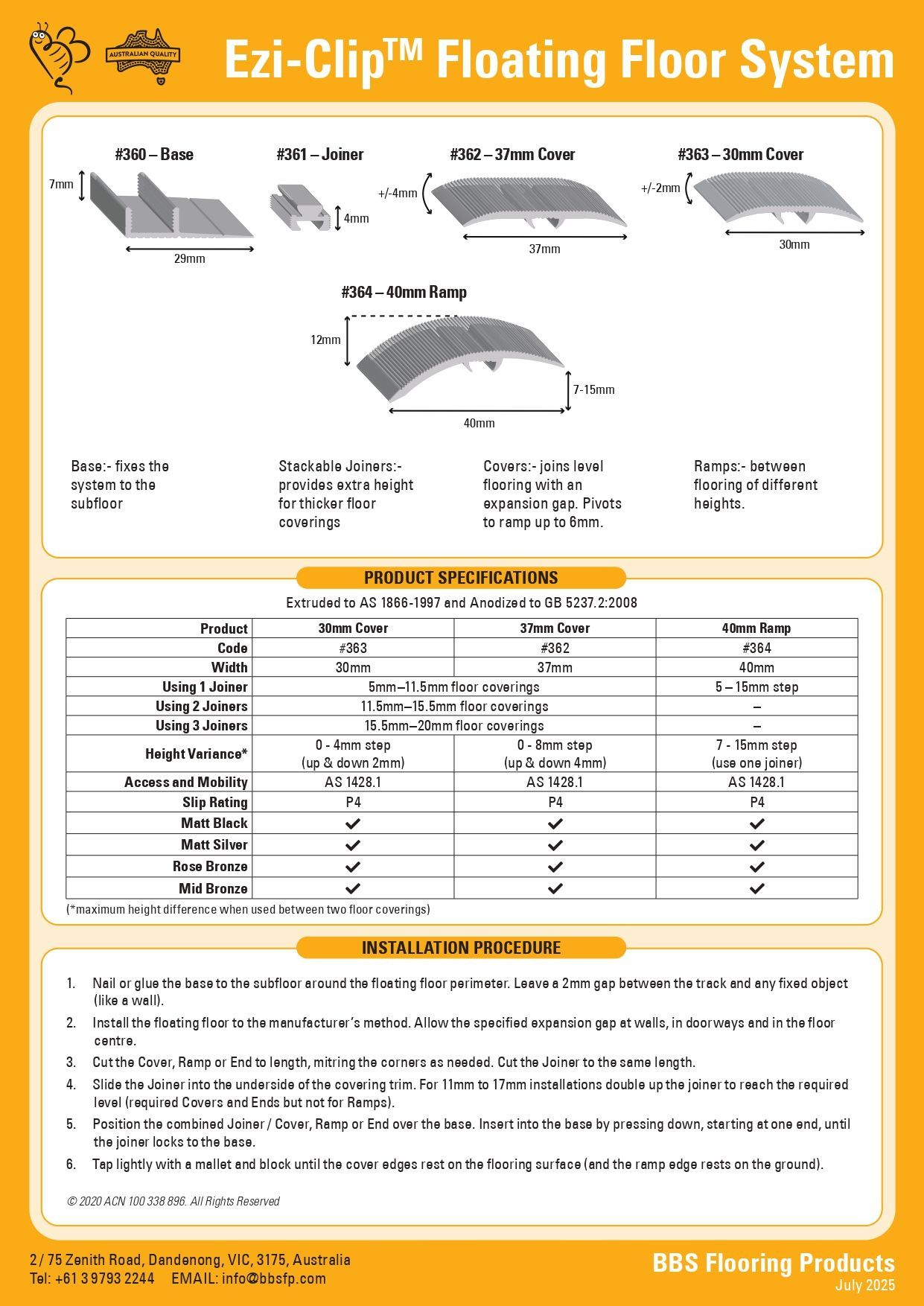

MANUFACTURING STANDARDS

All aluminium sections are extruded to AS 1866-1997, anodized to GB 5237.2:2008 or powder coated to GB 5237.5:2008.

FIRE TESTING

Mean Critical Radiant Flux (MCRF) tested to AS 9239.1.2003

BCA C1.10 2012, Table 2 lists the maximum CRF for Floor Covering Materials in different building types, (with and without a E1.5 sprinklers) and in Fire-Isolated Exists and Fire Control Rooms.

BBS aluminium sections show CRF of 12.9kW/m₂.

BBS Luminous Contrasting Strips show a CRF of 8kW/m₂.

Both measures meet the standard in all building types.

Mean Smoke Development Rate (MSDR) tested to AS 9239.1.2003

BCA C1.10 2012, 3 (b) determines a maximum MSDR of 750%-minutes in buildings not protected by a E1.5 sprinkler.

BBS aluminium sections show a MSDR of 2%-minutes.

BBS Luminous Contrasting Strips show a MSDR of 410%-minutes.

Both measures meet the standard in all building types.

Refer to BCA C1.10 2012 for detailed requirements.

LOAD RATINGS

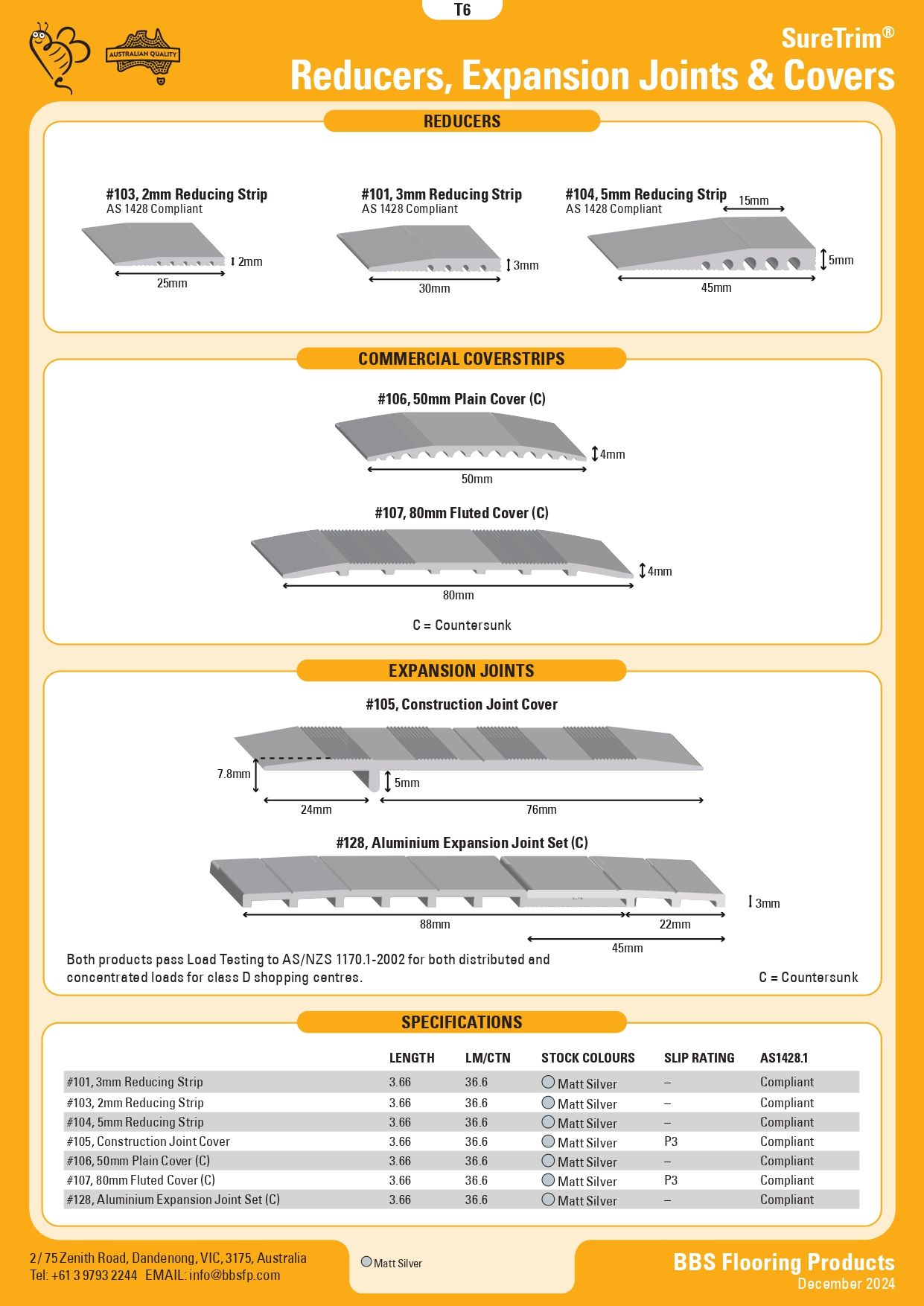

Load testing is conducted to AS/NZS 1170.1:2002 on expansion joints and covers that transition expansion gaps and joints.

They are tested for distributed loads up to 4.0kPa and concentrated loads up to 3.6kN which are required in class D shopping centres.

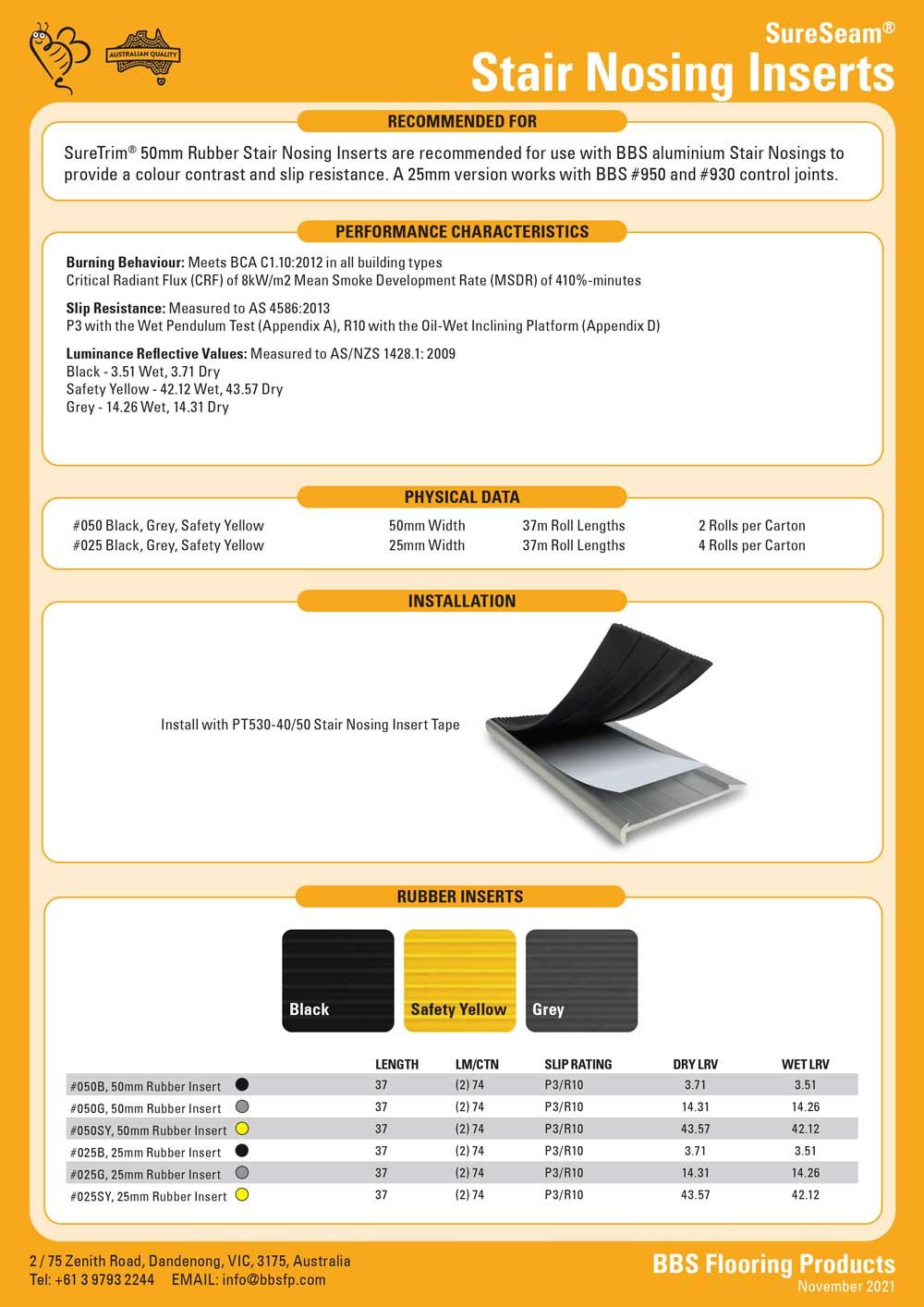

INSERT LUMINESCENCE

ASTM E2072-14 requires that luminescence (after activation has ceased) is not less than 30 mcd/m2 at 10 minutes and 5 mcd/m2 at 90 minutes

SLIP RATINGS

AS 4586:2013, Slip Resistance Classification of New Pedestrian Surface Materials governs slip ratings for pedestrian surfaces.

SA HB 198:2014 defines the tests for Floorcovering Materials:

- Wet Pendulum Test (App. A) in most locations (P0-P5).

- Oil-Wet Inclining Platform (App. D) for oil contaminated areas (R9-R13).

The minimum classifications deemed-to-satisfy building applications in the National Construction Code are:

| APPLICATION | DRY CONDITIONS | WET CONDITIONS |

|---|---|---|

| Ramp steeper than 1:14 | P4 or R11 | P5 or R12 |

| Ramp steeper than 1:20 but not steeper than 1:14 | P3 or R10 | P4 or R11 |

| Tread or landing surface | P3 or R10 | P4 or R11 |

| Nosing or landing edge strip | P3 | P4 |

The minimum classifications for applications where the National Construction Code does not stipulate Slip Resistance are considered to be:

External Pavements and Ramps

| LOCATION | WET PENDLUM | OIL-WET INCLINING PLATFORM |

|---|---|---|

| External ramps including sloping driveways, footpaths etc. steeper than 1:14 | P5 | R12 |

| External ramps including sloping driveways, footpaths etc., under 1:14 | P4 | R11 |

| External sales areas, carparks, colonnades, walkways, pedestrian crossings | P4 | R11 |

| External balconies, verandas, carports, driveways, courtyards and roof decks | P4 | R11 |

| Undercover car parks | P3 | R10 |

Hotels, Offices, Public Buildings, Schools and Kindergartens

Entries to hotels, offices, public buildings, schools, kindergartens, common areas of public buildings, internal lift lobbies:

| LOCATION | WET PENDULUM | OIL-WET INCLINING PLATFORM |

|---|---|---|

| Wet Area | P3 | R10 |

| Transitional Area | P2 | R9 |

| Dry Area | P1 | R9 |

| Toilet Facilities in offices, hotels and shopping centres | P3 | R10 |

| Hotel apartment bathrooms, ensuites and toilets | P2 | A |

| Hotel apartment kitchens and laundries | P2 | R9 |

Supermarkets and Shopping Centres

| Fast food outlets, buffet food servery areas, food courts etc. | P3 | R10 |

|---|---|---|

| Shop and supermarket fresh fruit and vegetable areas | P3 | R10 |

| Shop entry areas with external entrances | P3 | R10 |

| Supermarket aisles (except fresh fruit areas) | P1 | R9 |

| Other separate shops inside shopping centres - wet | P3 | R10 |

| Other separate shops inside shopping centres - dry | P1 | R9 |

Loading docks, Commercial Kitchens, Cold Stores, Serving areas

| Loading docks undercover and commercial kitchens | P5 | R12 |

|---|---|---|

| Serving areas behind bars in public hotels and clubs, cold stores and freezers | P4 | R11 |

Swimming pools and Sporting Facilities

| Swimming pool ramps and stairs leading to water | P5 | C |

|---|---|---|

| Swimming pool surrounds and communal shower rooms | P4 | B |

| Communal changing rooms | P3 | A |

| Undercover concourse areas of sports stadiums | P3 | R10 |

Hospitals and Aged Care Facilities

| Bathrooms and ensuites in hospitals and aged care facilities | P3 | B |

|---|---|---|

| Wards and corridors in hospital and aged care facilities | P2 | R9 |

Refer to AS 4586:2014 and its amendments for detailed requirements.

AS 1428.1 EXPLAINED

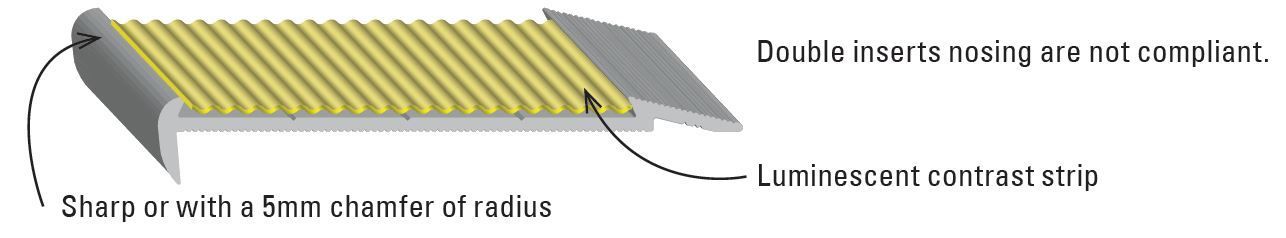

Stair nosings must not project beyond the face of the riser

They should sit flush with the riser. ‘Bullnosings’ and other projecting nosings are not compliant.

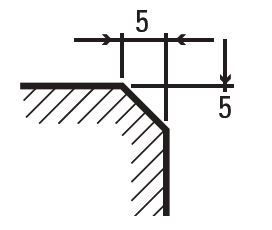

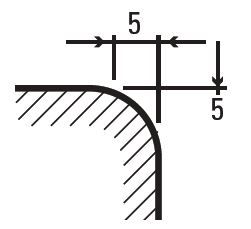

The leading edge of the stair nosing must either be sharp, or no more than a 5mm chamfer or radius.

Stair nosings must have a single luminance contrast strip between 50mm and 75mm wide.

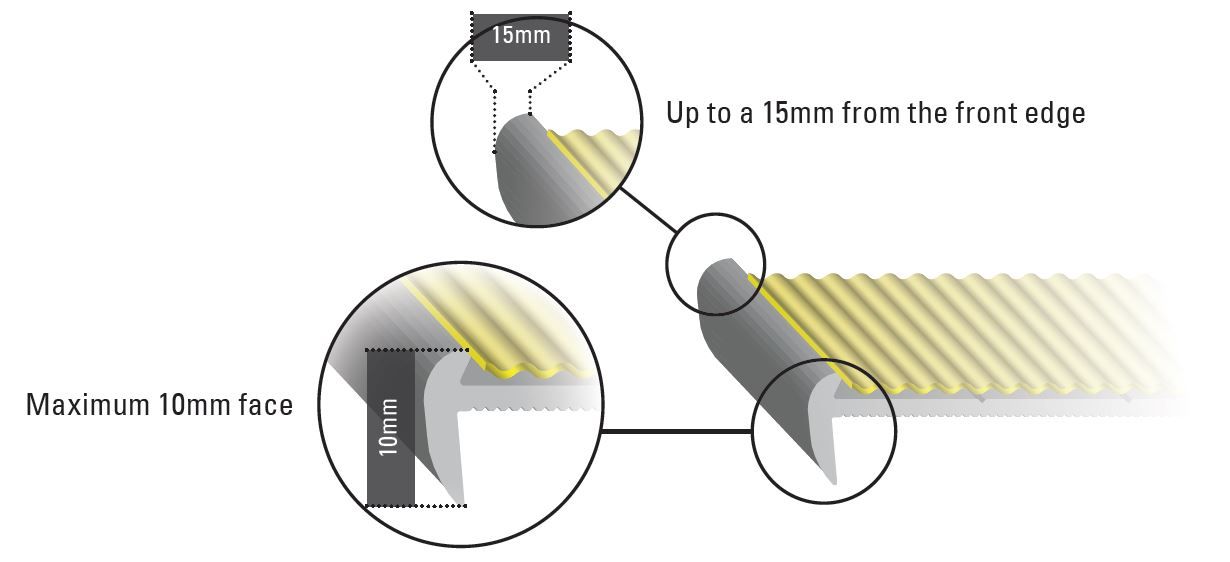

The luminance contrast strip can be set back up to 15mm from the leading edge

The luminance contrast strip must have a colour contrast of >30% to the background

Colour contrast is determined by comparing the Luminance Reflective Values (LRVs) of the luminance contrast strip to the background using an online calculator. LRVs go from 1 (black) to 100 (white). Floor coverings come with LRV certificates. LRVs for our luminance contrast strips are shown below. Use the ‘wet’ or ‘dry’ reading as appropriate.

The luminance contrast should not extend down the riser more by than 10mm

Where the nosing face is greater than 10mm it produces its own colour contrast and LRV. With 3 LRVs’ (nosing, contrast strip and background) you can’t get one clear contrast.

However… the LRV for the nosing can be ignored where the face is 10mm or less, or where the stair nosing LRV is the same as the background LRV. Since it is uncommon for nosing to colour match with the background stair or floor covering, compliance is easier to achieve with a 10mm face on the nosing.